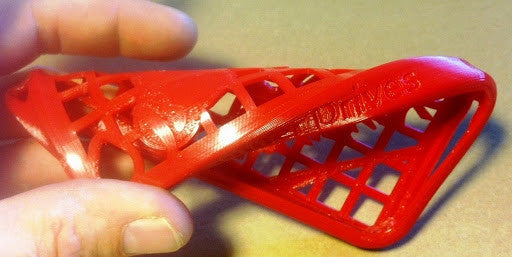

Type A Experimental Filament: Ninjaflex (priced per gram)

Ninjaflex Settings in Cura:

-

Layer height: 0.3

-

Walls: 0.8

-

Infill Distance: 4åÊ

-

Print Speed: 15

-

Support: 0

-

Retraction Speed: 30

-

Retraction Distance: 1.8

-

Printing Temp: 220

-

Bed Temp: 40

NinjaFlex has developed quite a following in 3D printing circles because it's a very durable filament which is completely flexible. The flexibility of this filament actually makes it quite resilient and sturdy. NinjaFlex is great for creating household goods like iPhone or iPad cases.

Features:

Filament shore hardness of approximately 85A

Consistent diameter and material properties provide reliable, high quality prints

Patent pending technology allows for smooth feeding

Low tack, low CoF exterior allows smooth feed through filament guides

High elasticity and excellent abrasion resistance

Excellent build platform adhesion and bonding between layers

REACH and RoHS 2002/95/EC Directive Compliant

1.75mm filament spool = .50 kg

3.00mm filament spool = .75 kg

FAQs

I am unable to get NinjaFlex to feed. Any suggestions?

In order for flexible filaments such as NinjaFlex to feed properly, a spring-loaded feed mechanism with a roller bearing is required. Also, the extruder must support the filament between the exit of the drive gear and the entrance to the melt chamber.

Will NinjaFlex feed well through plastic guide tubes?

While the low coefficient of friction surface of NinjaFlex has been formulated to reduce surface tack and allow the filament to feed more easily, the use of PTFE guide tubes may be beneficial to further reduce pull at the extruder.

Are there any special printer settings that need to be adjusted for NinjaFlex?

NinjaFlex generally works well at similar extruder settings to ABS, however adjusting the printer's retraction settings can improve stop/start print quality. Also, it may be necessary to reduce the print speed to approximately 30mm/s.

My prints are coming out stringy. What can I do to improve quality?

The strings are caused by the material not freezing off quickly enough at stop/start. There are multiple factors that come into play: extruder temperature, build platform temperature, ambient temperature, and retraction settings. As the melted filament comes out of the extruder, it should have just enough energy to re-melt the existing surface (to provide adequate bonding). The colder the ambient, the build platform, and the starting temperature of the filament, the more quickly it will freeze off. If temperatures cannot be adjusted, the amount of filament that is retracted at start stop may be increased. For 1.75mm filament, 2-3mm of retraction works well. Another option is to increase convection heat transfer with a ducted cooling fan.

Is NinjaFlex food or medical grade?

Although NinjaFlex does not contain BPA or other toxins, it is not recommended for food or medical applications.

Is NinjaFlex water resistant?

While occasional contact with water will have no adverse effect on NinjaFlex, the product will degrade and lose its elastic properties when submerged in water for extended periods of time.

What is the maximum recommended temperature for printed NinjaFlex parts?

The recommended maximum temperature for NinjaFlex printed parts is 150å¡F.

What is the minimum recommended temperature for printed NinjaFlex parts?

The recommended minimum temperature for NinjaFlex printed parts is -22å¡F. Below this temperature, printed parts will become increasingly brittle and may shatter.

Is a heated build plate required in order to print with NinjaFlex?

While each printer may have unique settings, in most printers, a heated build plate is not required in order to successfully print with NinjaFlex.

Can NinjaFlex be used with support Material?

Yes, NinjaFlex works well in prints with support material and can easily be removed once the print is complete.

Any other tips for using NinjaFlex?

When switching from another polymer (such as ABS or PLA) purge thoroughly before starting a print. As with other materials, when preheating, use a lower Temperature (~180-200å¡C) to prevent excess material from draining prior to starting a print.

Is NinjaFlex colorfast?

NinjaFlex filament is colorfast, and therefore, the color will not leach from the product.

Is NinjaFlex chemical resistant?

While NinjaFlex is resistant to most oils, it is highly affected by solvents, acids, and fuels such as gasoline. If the printed part should need to be cleaned, a mild soap solution is recommended.

Does NinjaFlex hold Similar detail to ABS or PLA?

Yes, once printer settings are dialed in, NinjaFlex should deliver similar detail to rigid materials. For tall thin parts, supports may need to be designed-in to prevent the model from flexing as the print head traverses.

How can I bond NinjaFlex parts?

NinjaFlex has a very low surface energy, so it typically does not bond well with adhesives; however, Gorilla Glue seems to provide moderate bonding. The best way to connect NinjaFlex parts is with a hot knife welder.

Is NinjaFlex able to accommodate any bridging (crossing open unsupported spans)?

Yes, NinjaFlex behaves similarly to ABS in this regard and may be substituted in prints designed for ABS.

Are there any safety concerns or considerations when using NinjaFlex?

NinjaFlex should be used in a well-ventilated area according to recommended operating conditions. TPE products are capable of releasing small amounts of fumes at high temperatures. While these fumes are generally considered tolerable and less noxious than ABS, care should be taken to minimize exposure, particularly among sensitive persons.

Keywords: Ninja